ISO 3834 Certifications

ISO 3834 - Quality requirements for fusion welding of metallic materials

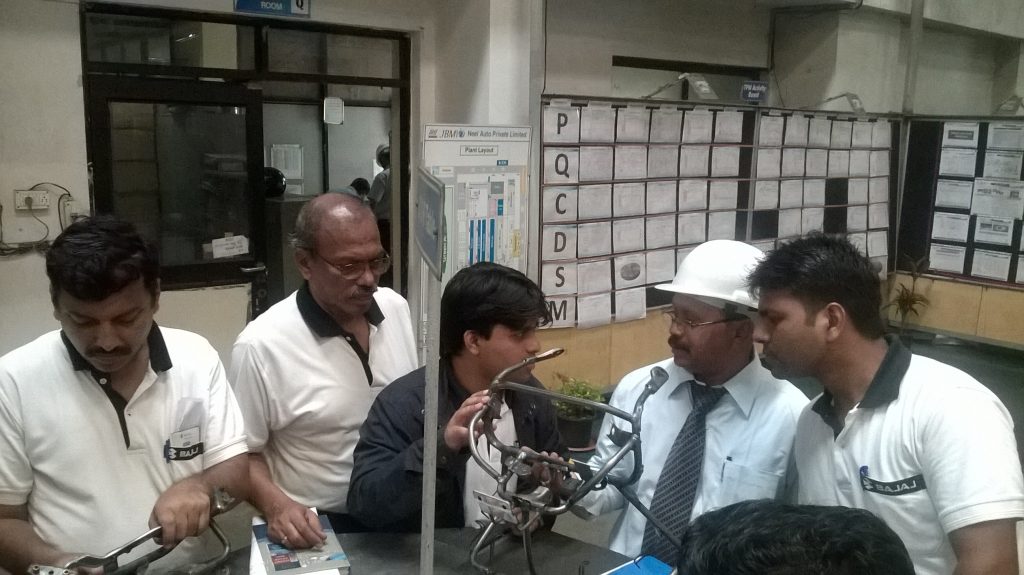

“ Quality cannot be inspected into a product, it has to be built in “ In material joining process , fusion welding are widely used to manufacture many products. In some companies, they are the key feature of production. Products may range from simple to complex. Examples include Railway components , pressure vessels, domestic and agricultural equipment, cranes, bridges, transport vehicles , automobile , power sectors , Mining & defence and other fabrications.

These processes exert a profound influence on the cost of manufacture and quality of the product. It is important, to ensure that these processes are carried out in the most effective way and appropriate control is exercised over all aspects of the operation. It is emphasised that ISO 3834 is not a quality management system standard replacing ISO 9001:2000. However, it can be a useful tool when ISO 9001:2000 is applied by the manufacturers. Specification of quality requirements for welding processes is important because the quality of these processes cannot be readily verified. Therefore, they are considered to be special processes as noted by ISO 9000:2000.

Part 1: Criteria for the selection of the appropriate level of quality requirements

Part 2: Comprehensive quality requirements

Part 3: Standard quality requirements

Part 4: Elementary quality requirements

Part 5: Documents with which it is necessary to conform to claim conformity to the quality requirements of ISO 3834-2, ISO 3834-3 or ISO 3834-4

NOTE : A Technical Report ISO/TR 3834-6, Quality requirements for fusion welding of metallic materials — Part 6: Guidance on implementing ISO 3834 is being prepared.

What are the benefits of using ISO 3834 standard for the manufacturer?

- Local and international recognition as a competent organization

- Meet the welding-related requirements of ISO 9001

- More efficient coordination of welding activities

- More pro-active and responsible workforce

- Increased opportunities and capability to bid on jobs

- Cost savings – more efficient technology

What are the benefits of specifying the ISO 3834 standard for the purchase & specifier.

More assurance of contract delivery dates

• Greater assurance of the quality of welded products

• Greater reliability and performance of plant

• Reduction in maintenance costs

• Reduction or elimination of third party inspection costs

• More competent suppliers of welded products.